Image 1 of 18

Image 1 of 18

Image 2 of 18

Image 2 of 18

Image 3 of 18

Image 3 of 18

Image 4 of 18

Image 4 of 18

Image 5 of 18

Image 5 of 18

Image 6 of 18

Image 6 of 18

Image 7 of 18

Image 7 of 18

Image 8 of 18

Image 8 of 18

Image 9 of 18

Image 9 of 18

Image 10 of 18

Image 10 of 18

Image 11 of 18

Image 11 of 18

Image 12 of 18

Image 12 of 18

Image 13 of 18

Image 13 of 18

Image 14 of 18

Image 14 of 18

Image 15 of 18

Image 15 of 18

Image 16 of 18

Image 16 of 18

Image 17 of 18

Image 17 of 18

Image 18 of 18

Image 18 of 18

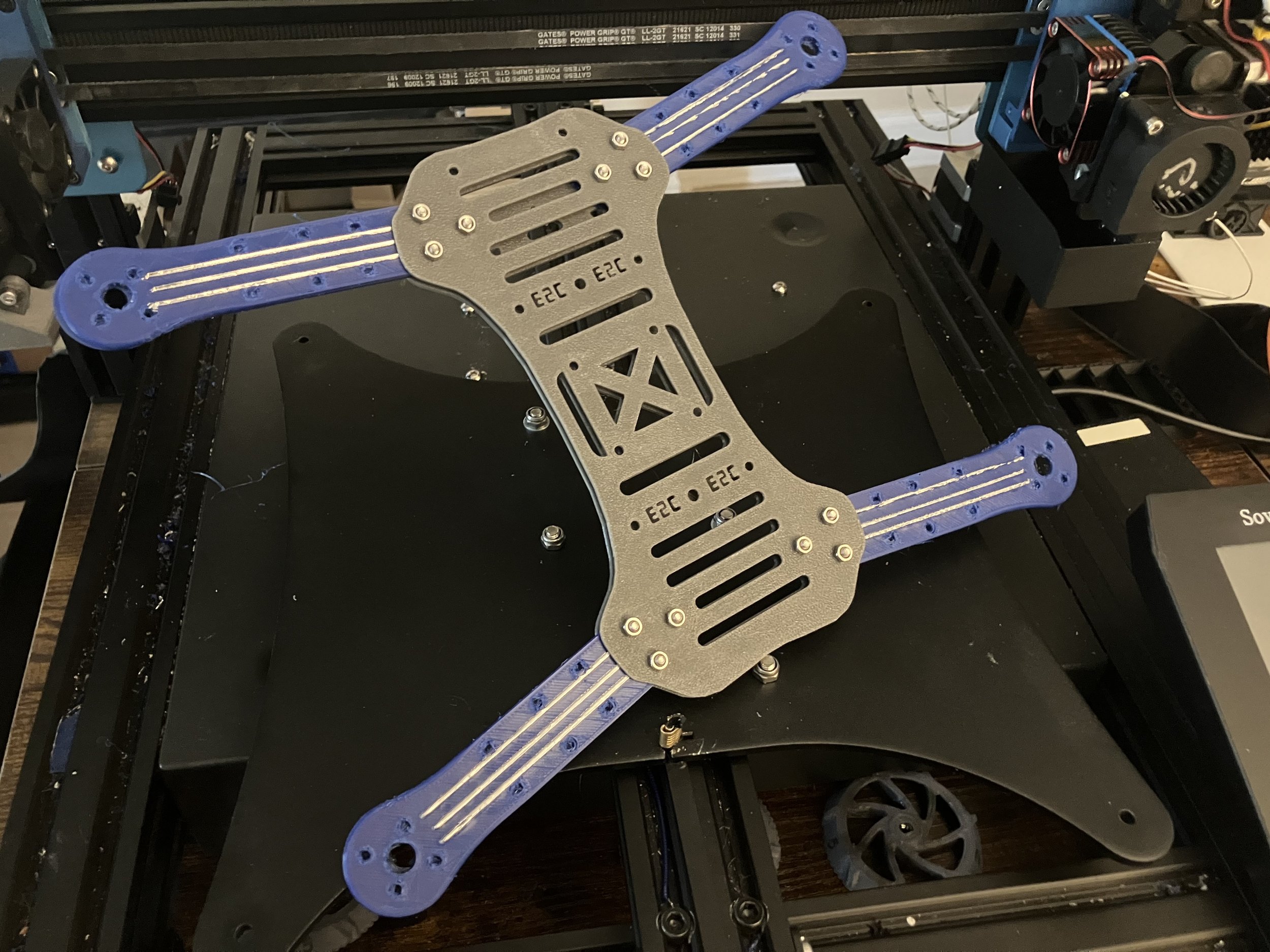

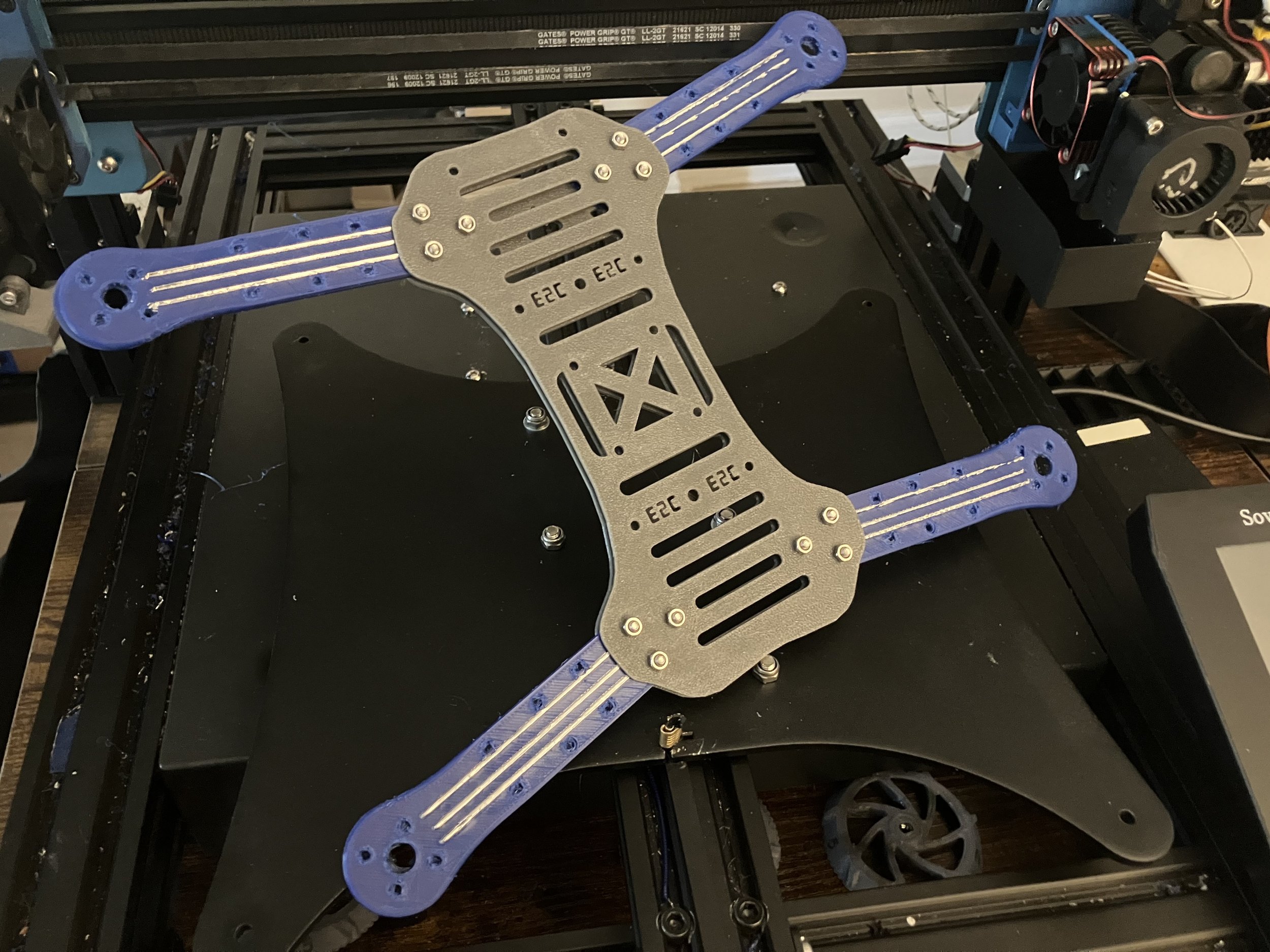

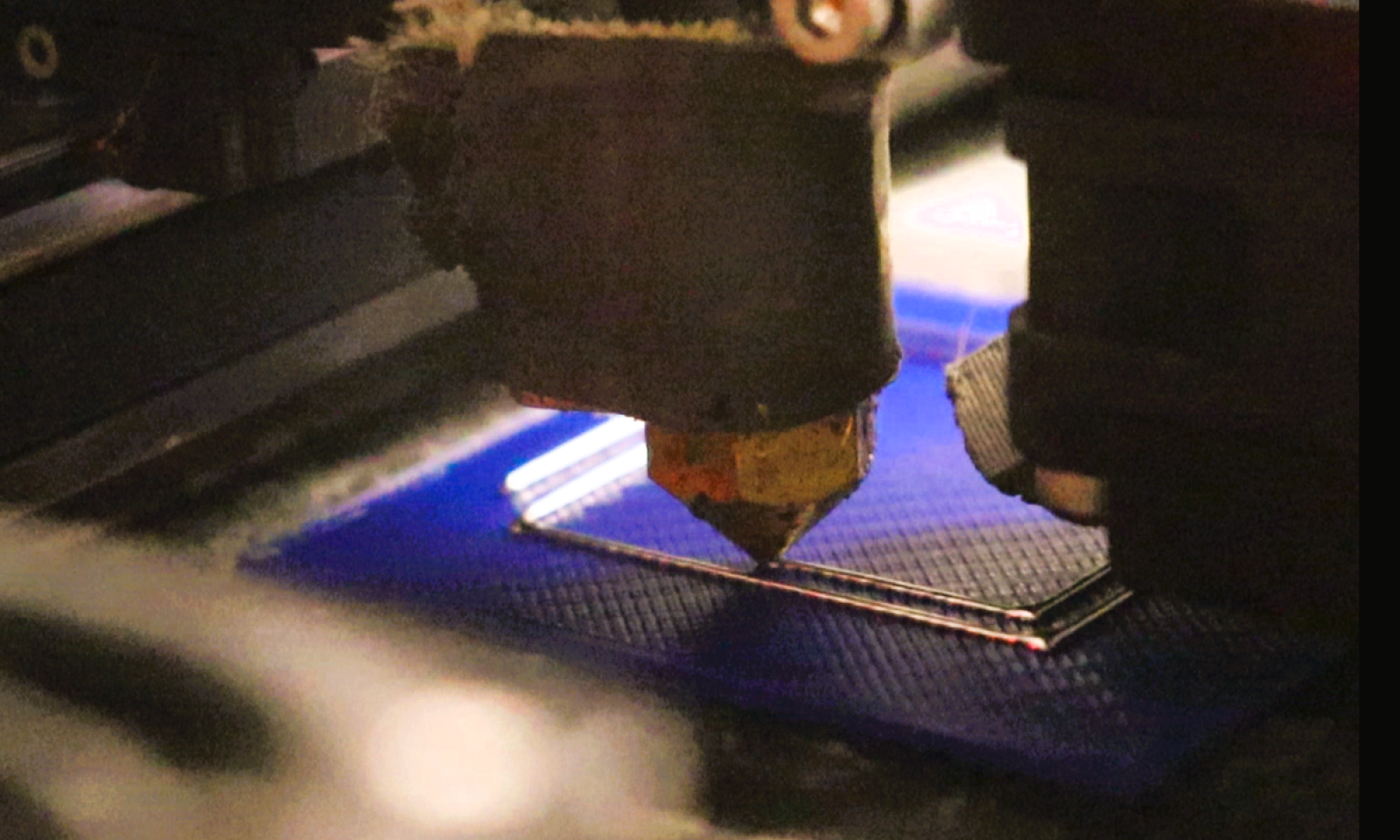

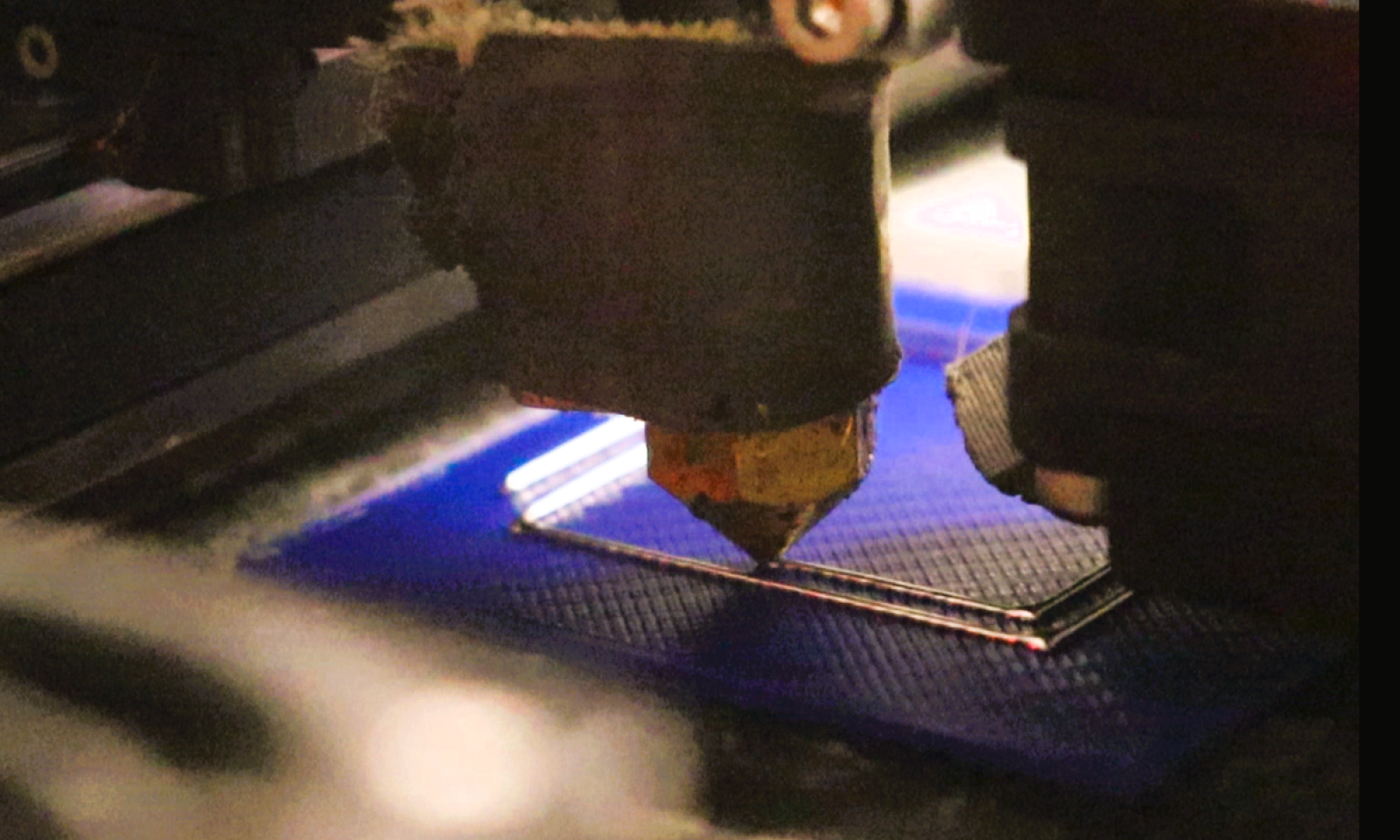

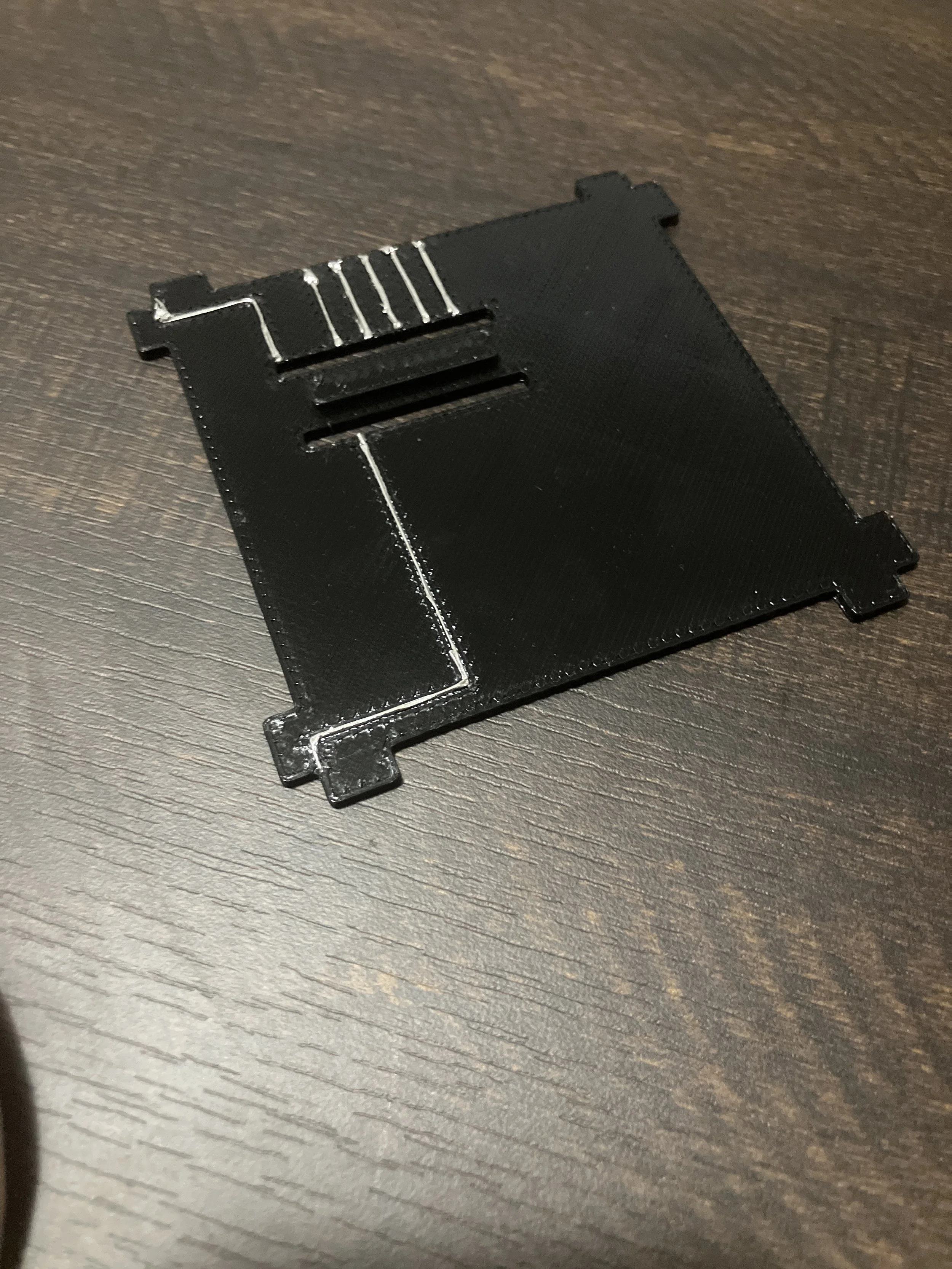

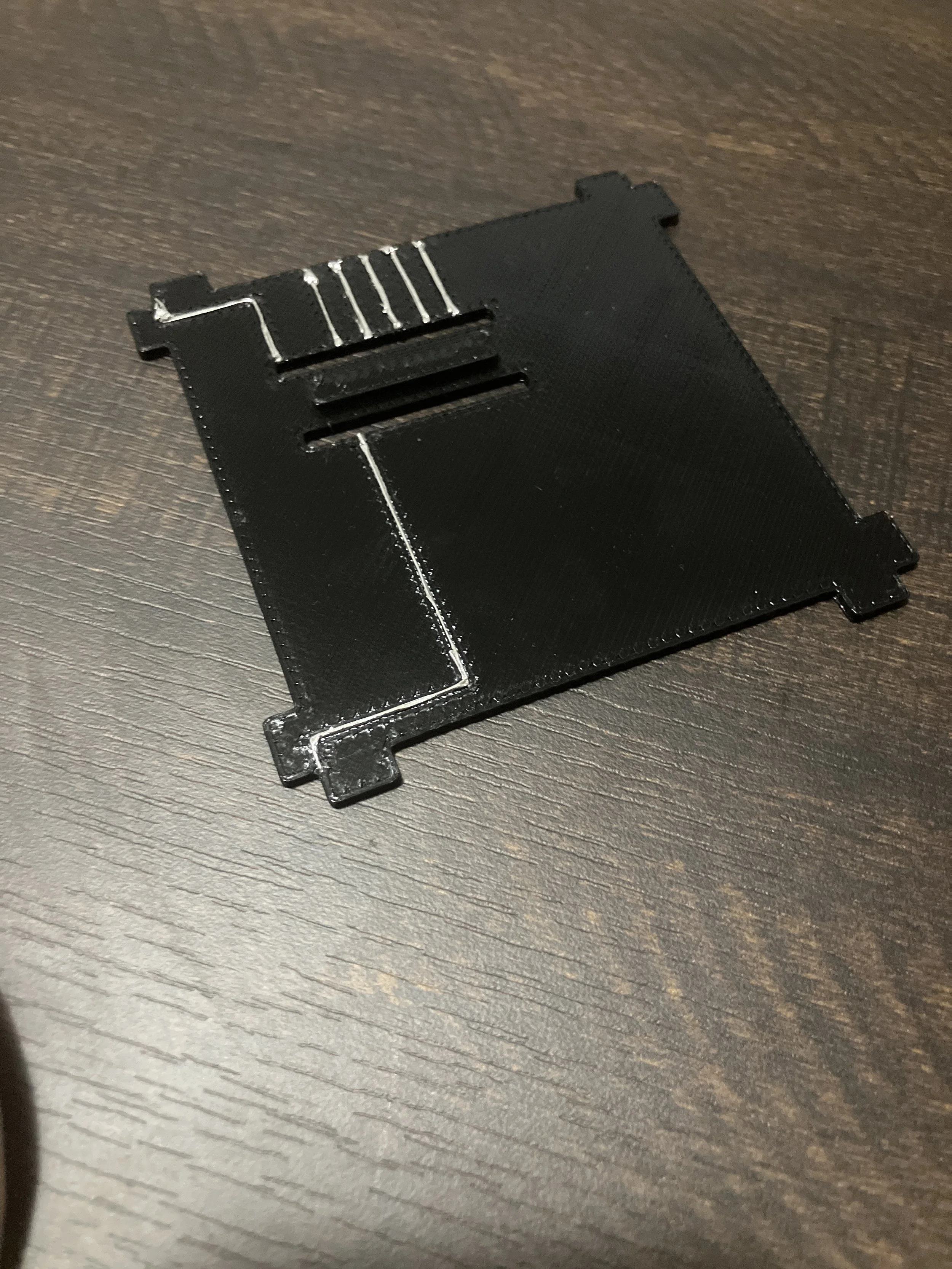

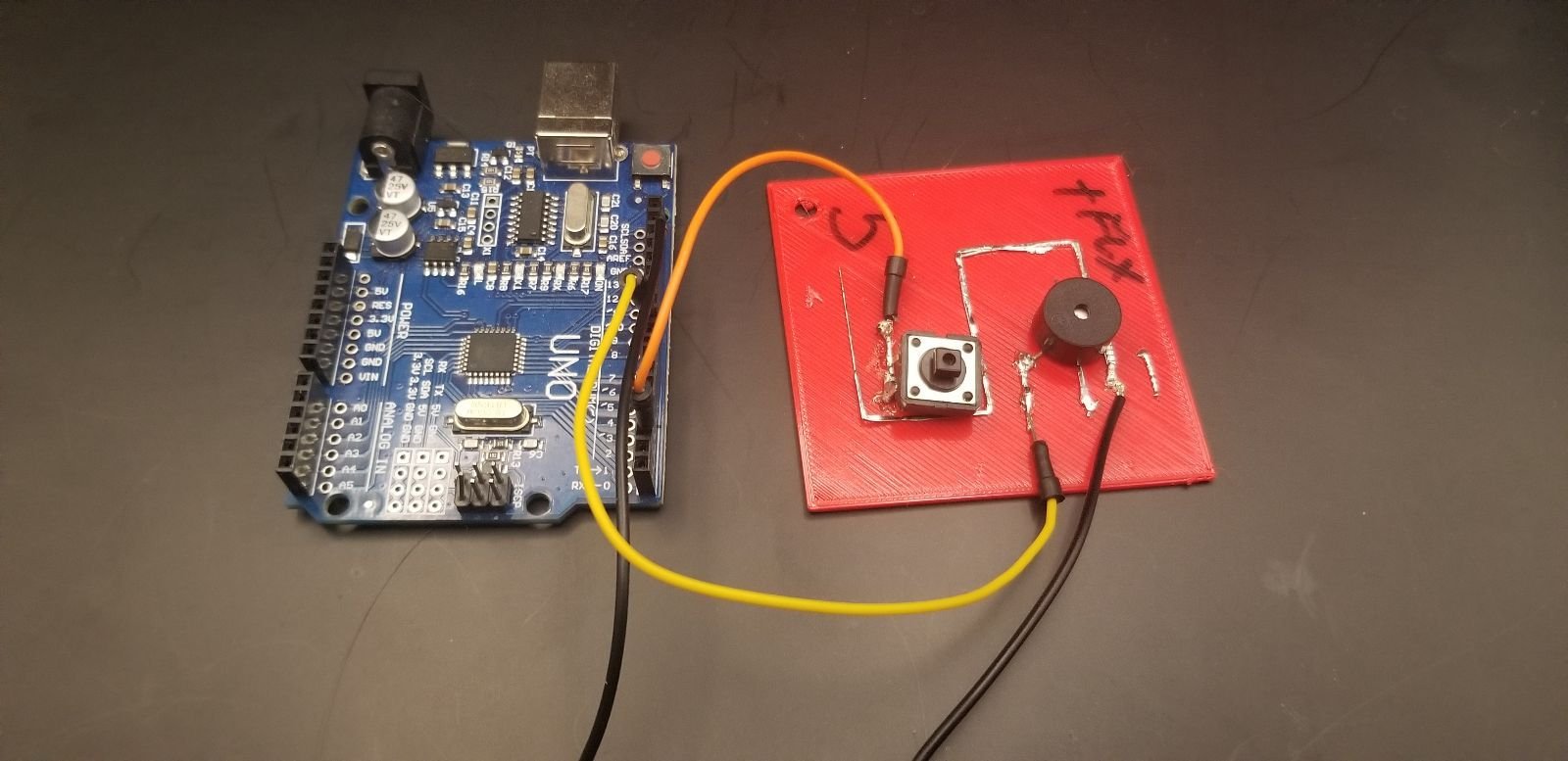

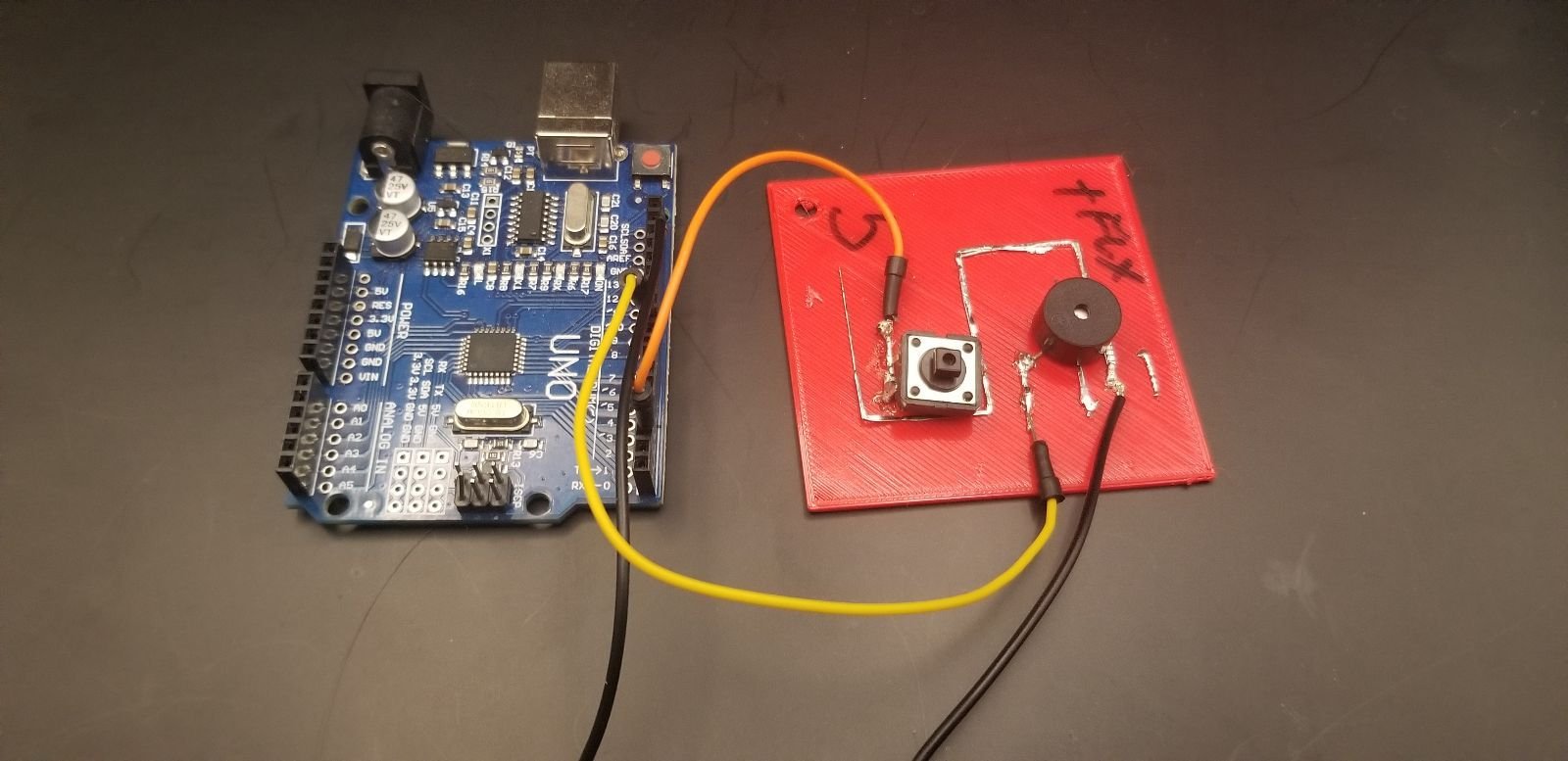

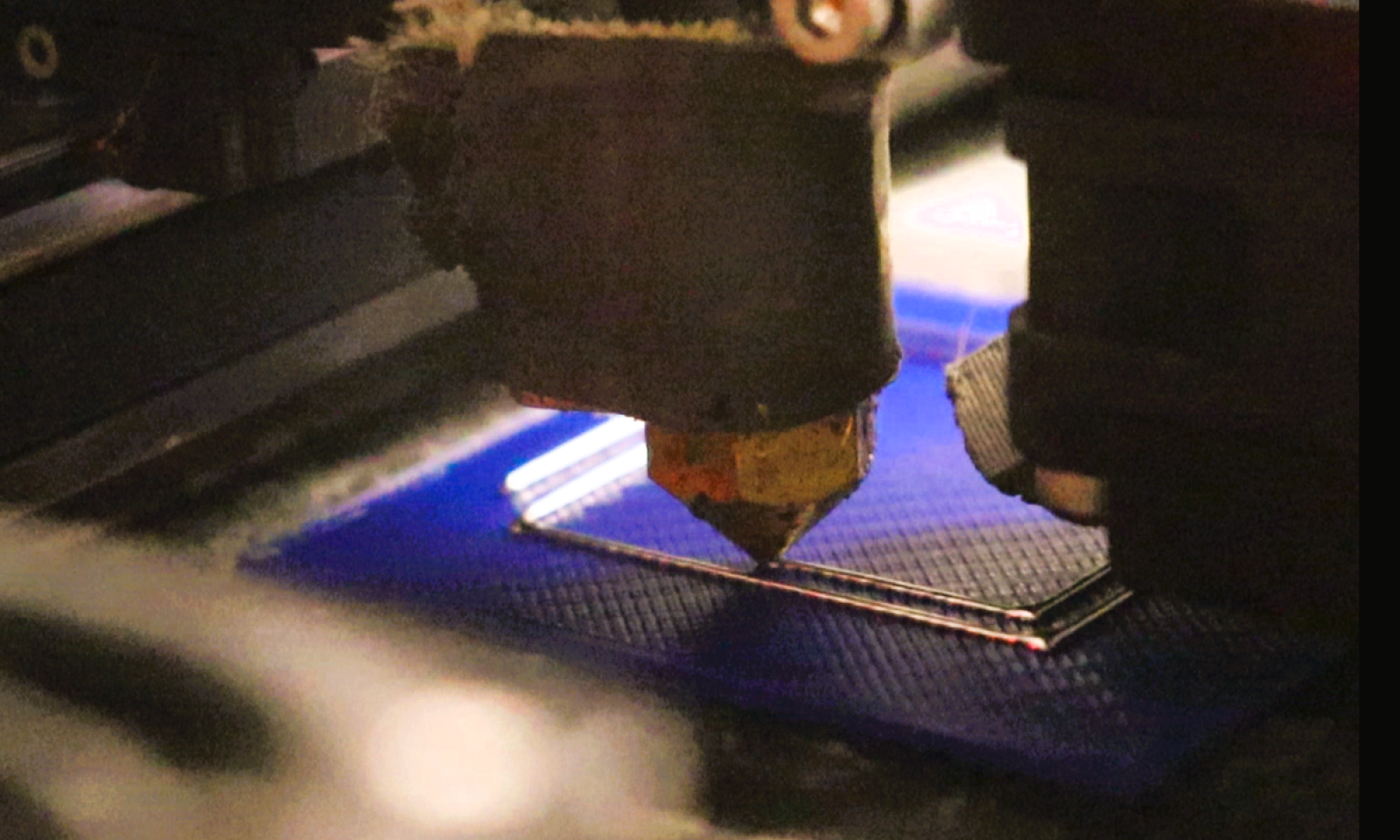

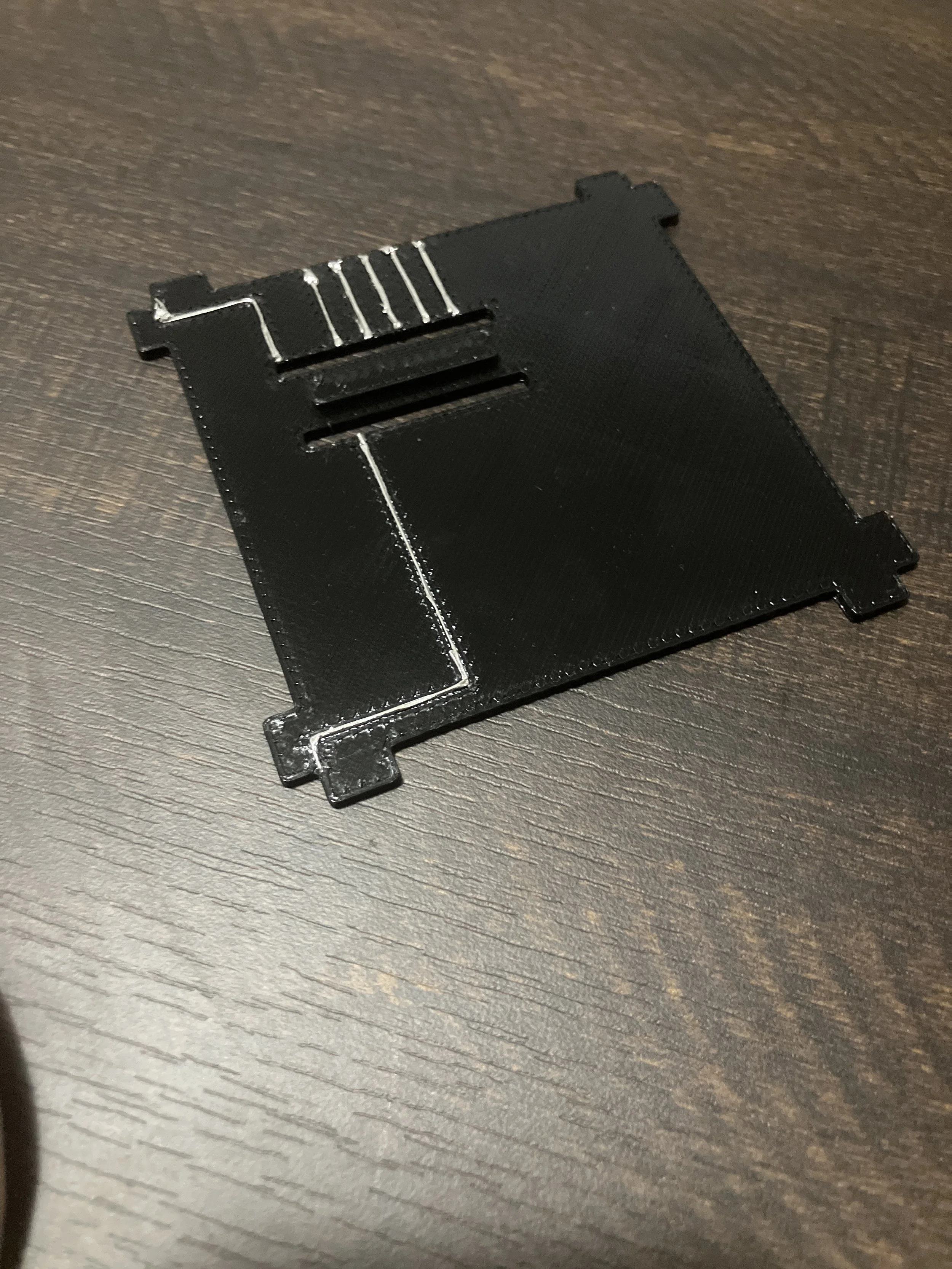

Cu-29 All-Metal Conductive Filament

Cu29™ All-Metal Conductive Filament for FDM/FFF 3D Printing

Power-grade conductivity. Zero post-processing. No million-dollar printer required.

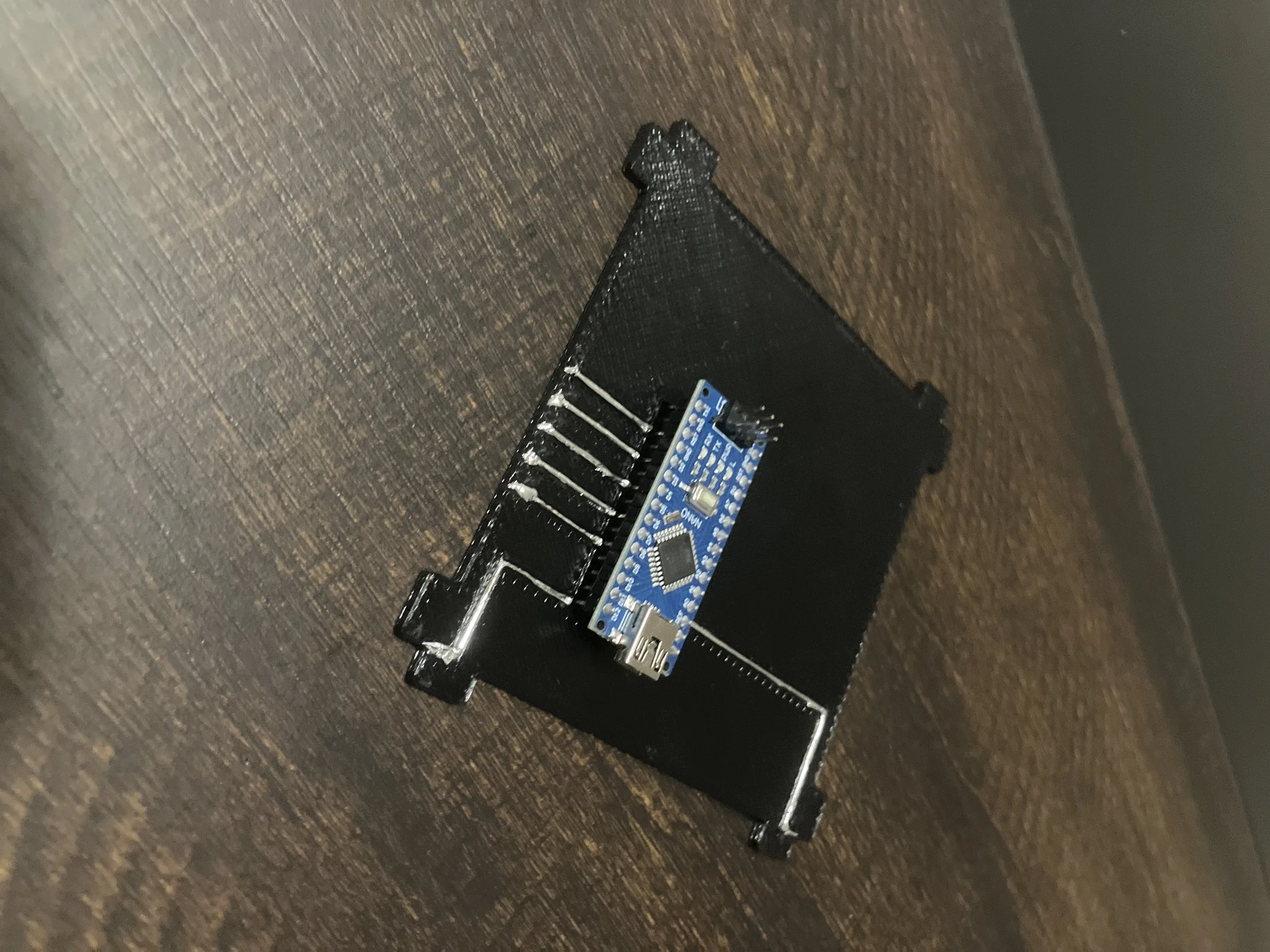

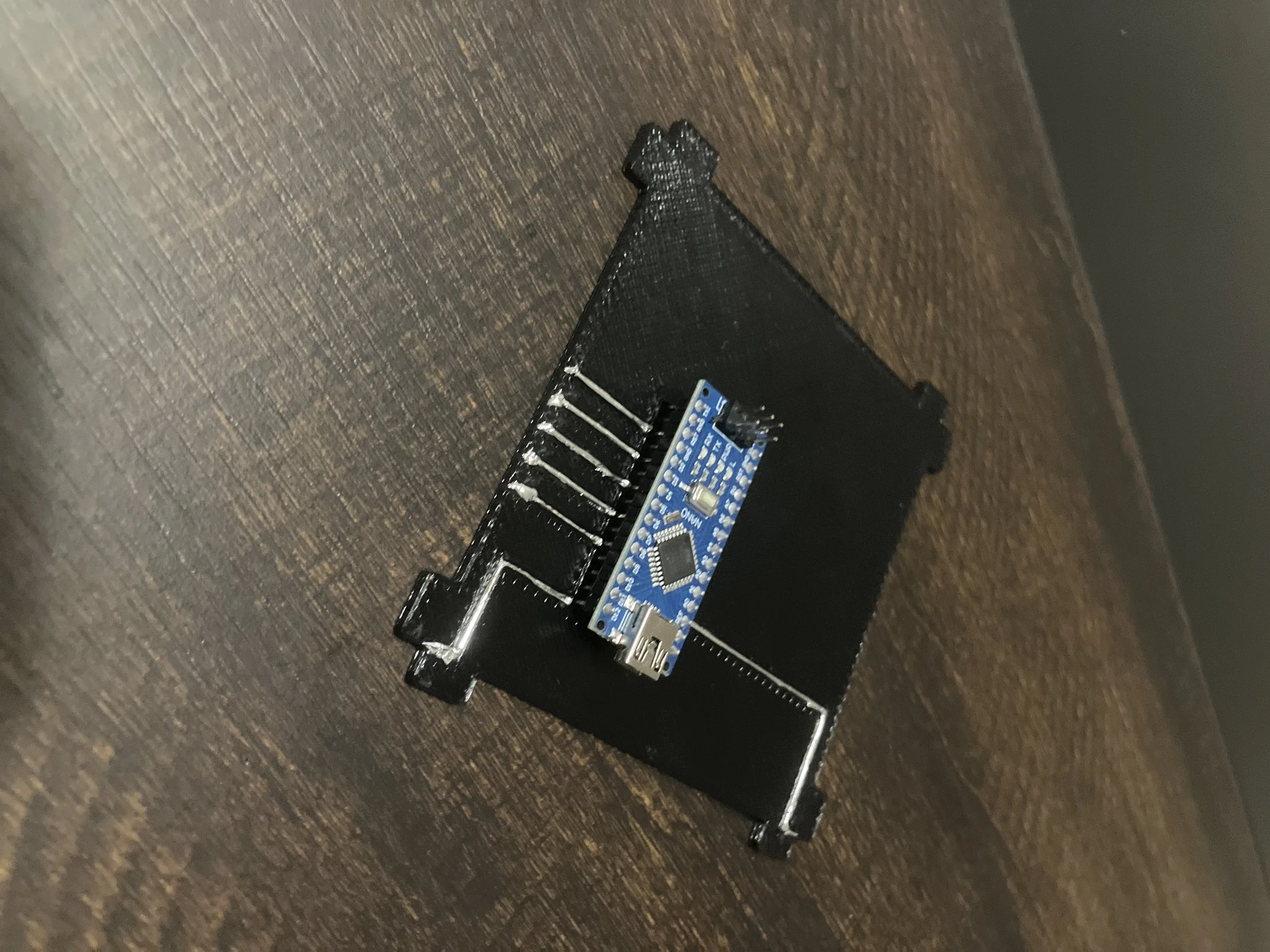

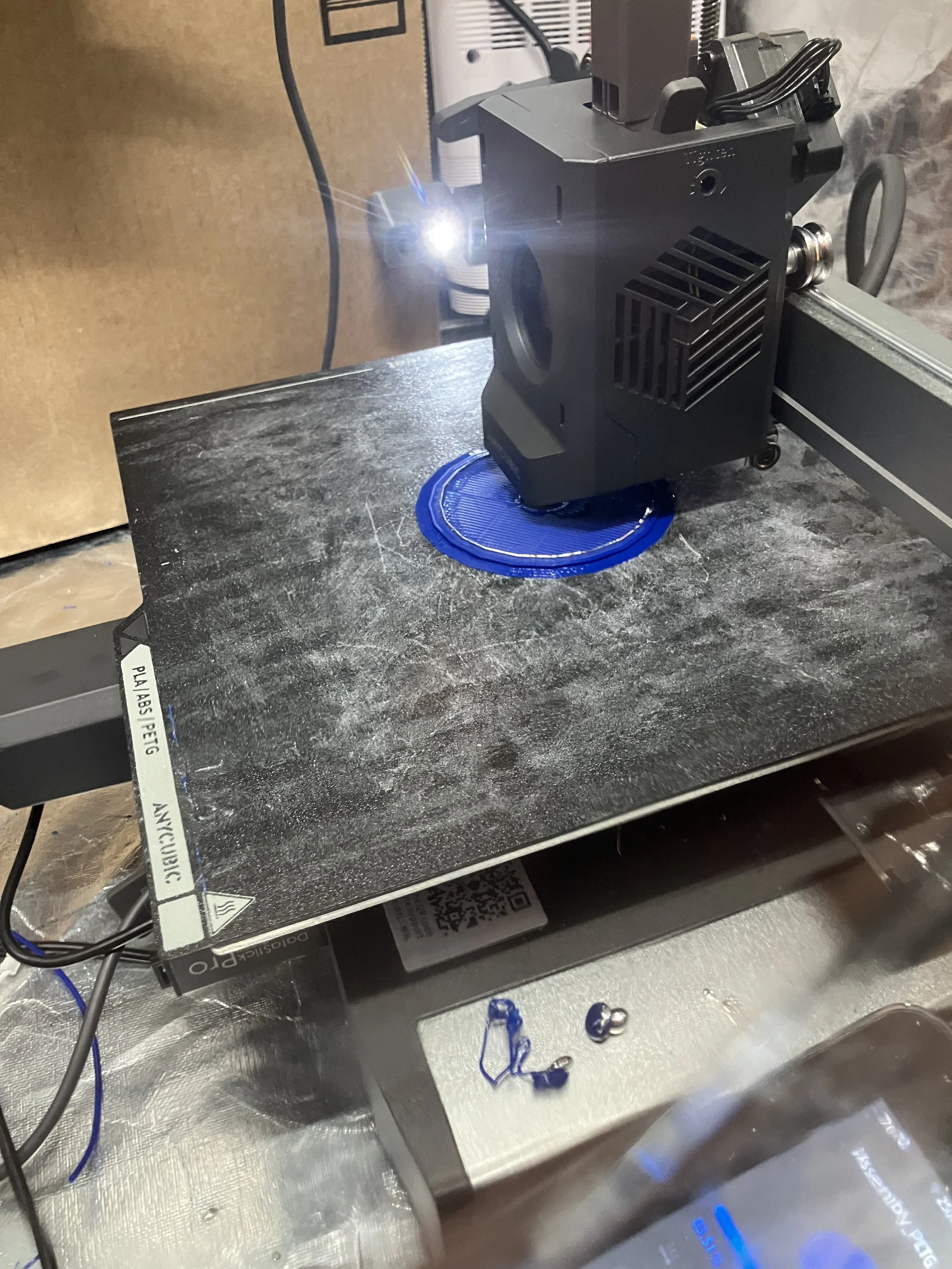

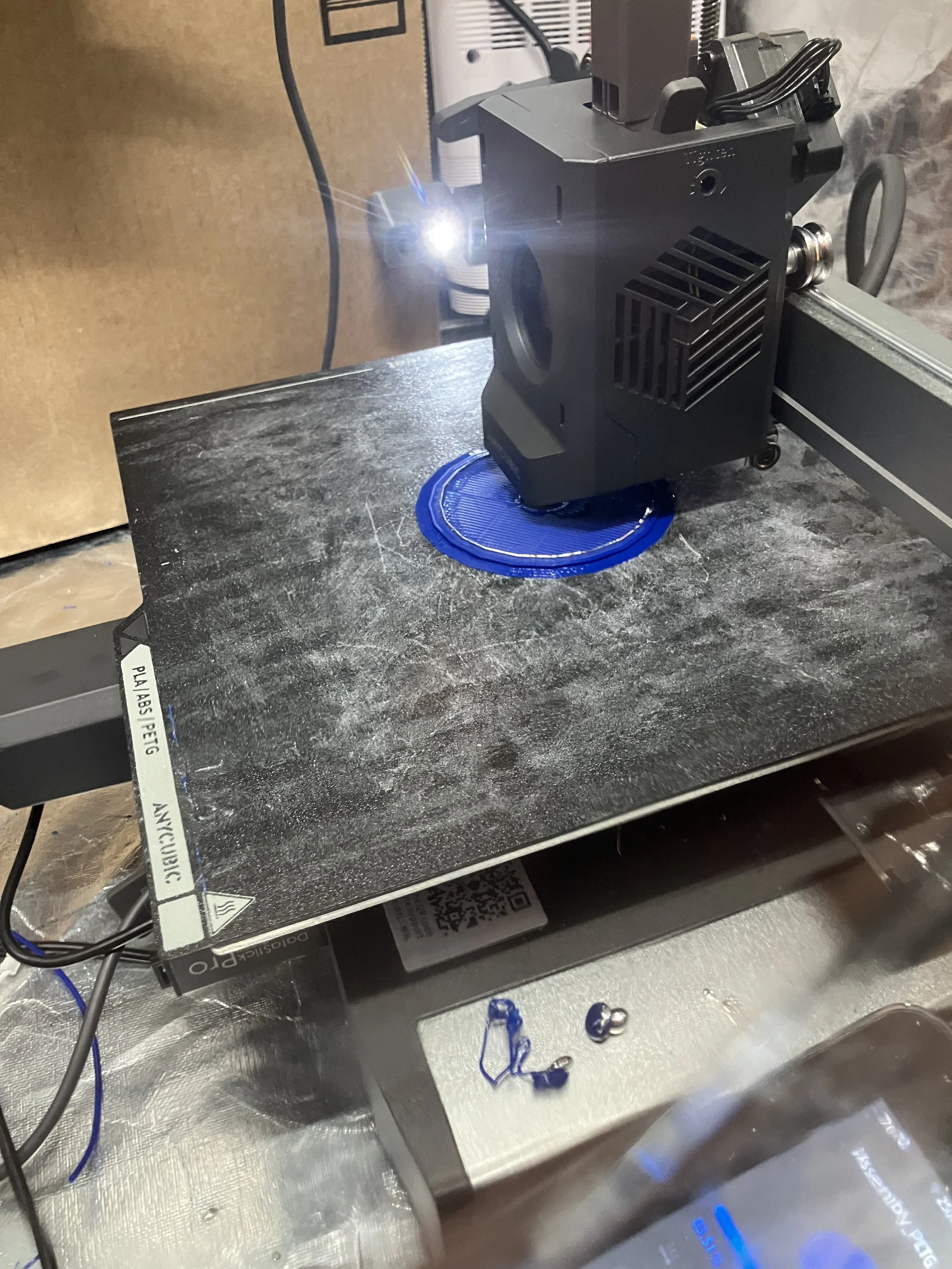

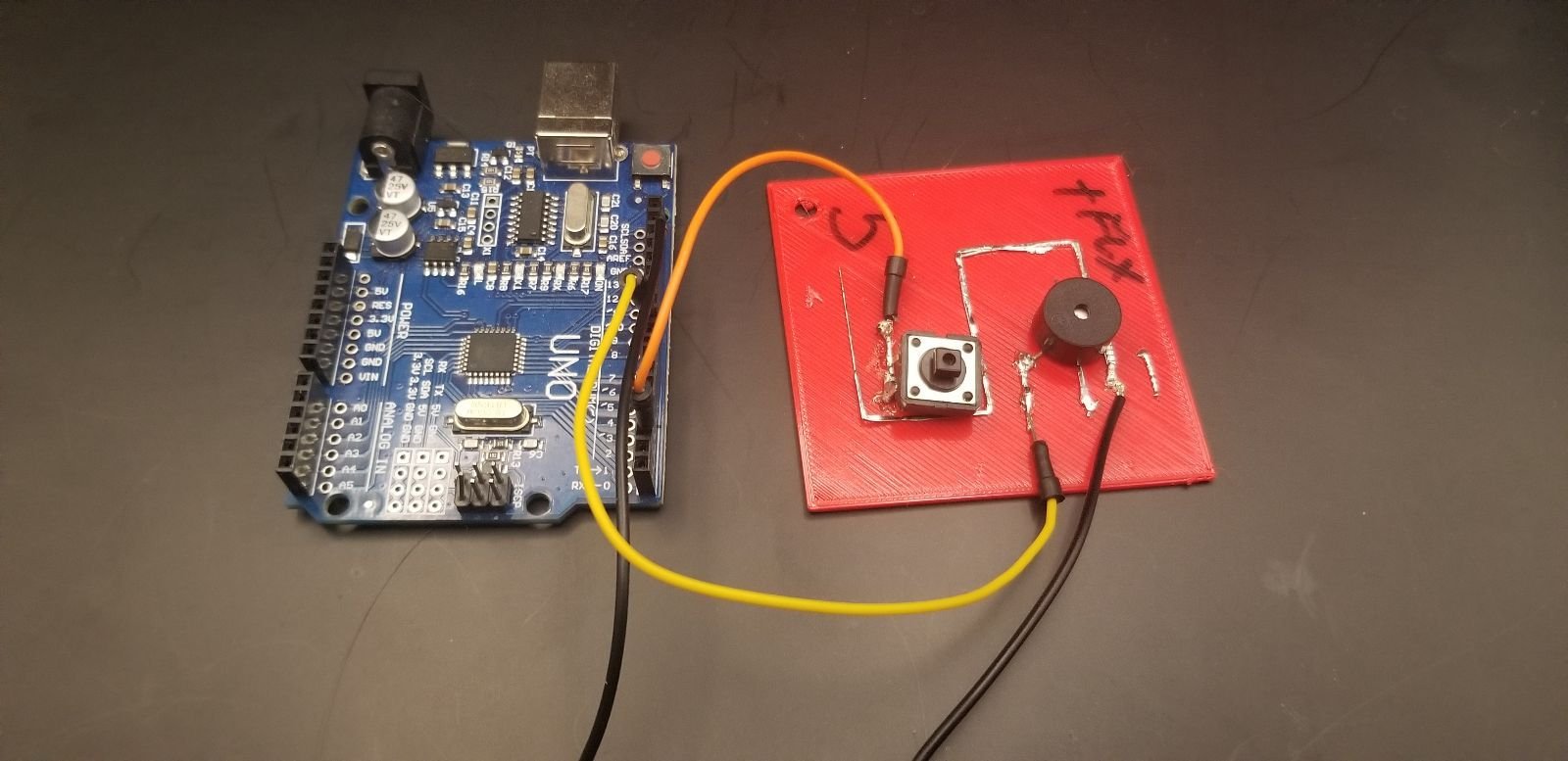

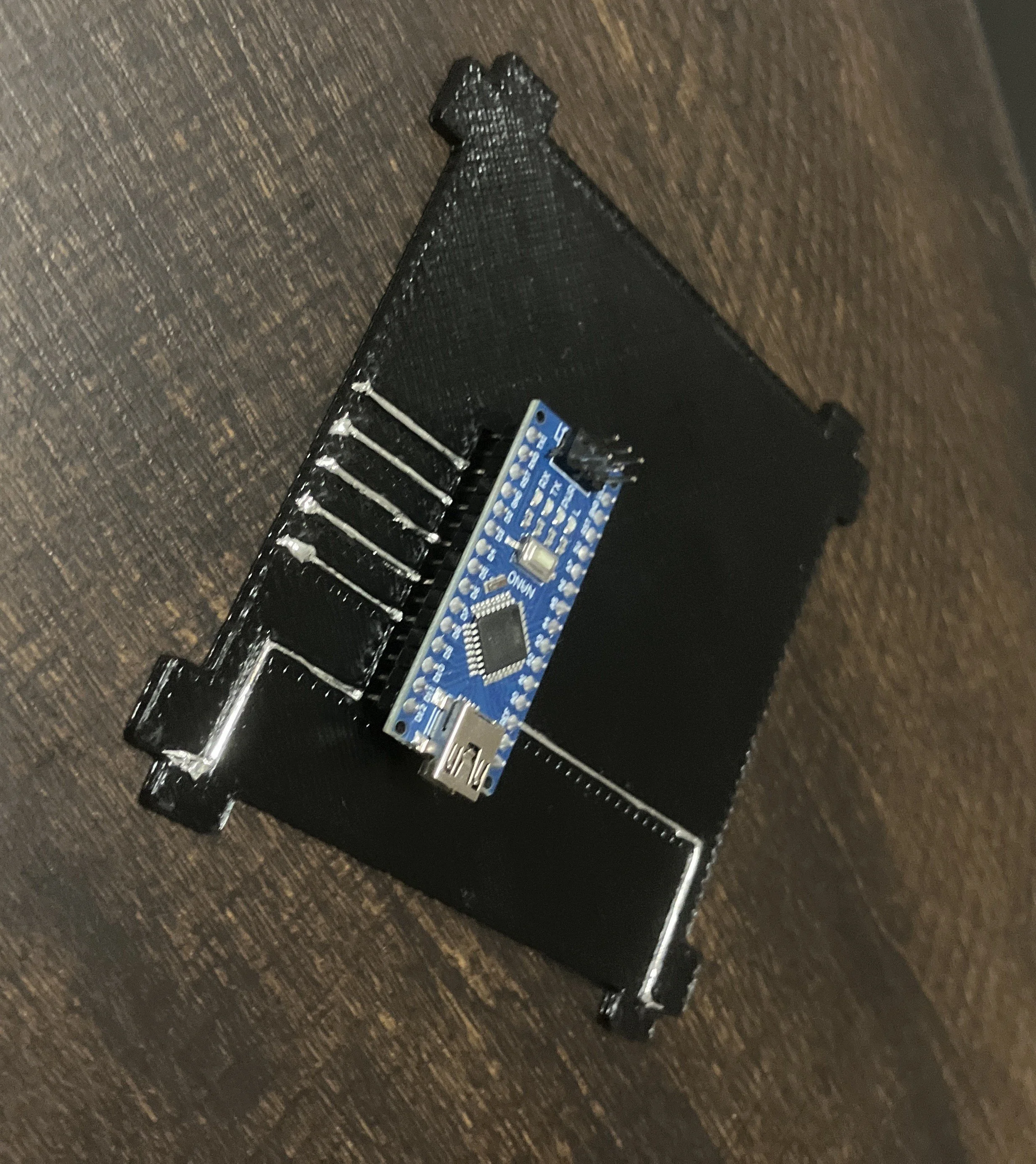

Kupros’ Cu29 is the world’s first all-metal, high-voltage and high-amperage conductive filament designed to bring industrial-grade Additive Manufactured Electronics (AME) to the desktop. Whether you’re printing embedded circuits, antennas, sensors, EMI shielding, or custom RF devices, Cu29 delivers unmatched conductivity and seamless integration into your polymer-based components, using off-the-shelf 3D printers or industrial printers.

Choose Your Trace Length

We’ve got four spool sizes depending on how deep you want to dive in:

50g – $250: Prints ~50 meters of average sized conductive traces

100g – $450: Prints ~100 meters of average sized conductive traces

0.5kg – $1,850: Prints ~½ kilometer of average sized conductive traces

1kg – $3,500: Prints ~1 kilometer of average sized conductive traces

Key Features

Massive Resistivity Advantage: 1.226×10⁻⁵ Ω⋅cm. That’s over 48,000% more conductive than polymer-based filaments.

True High-Voltage Performance: Validated at 12,500 volts and 5 amps.

No Post-Processing Required: No sintering, plating, curing, or chemical cleanup.

Precision Engineering: Supports traces as fine as 0.12 mm and up to 1.2 mm wide.

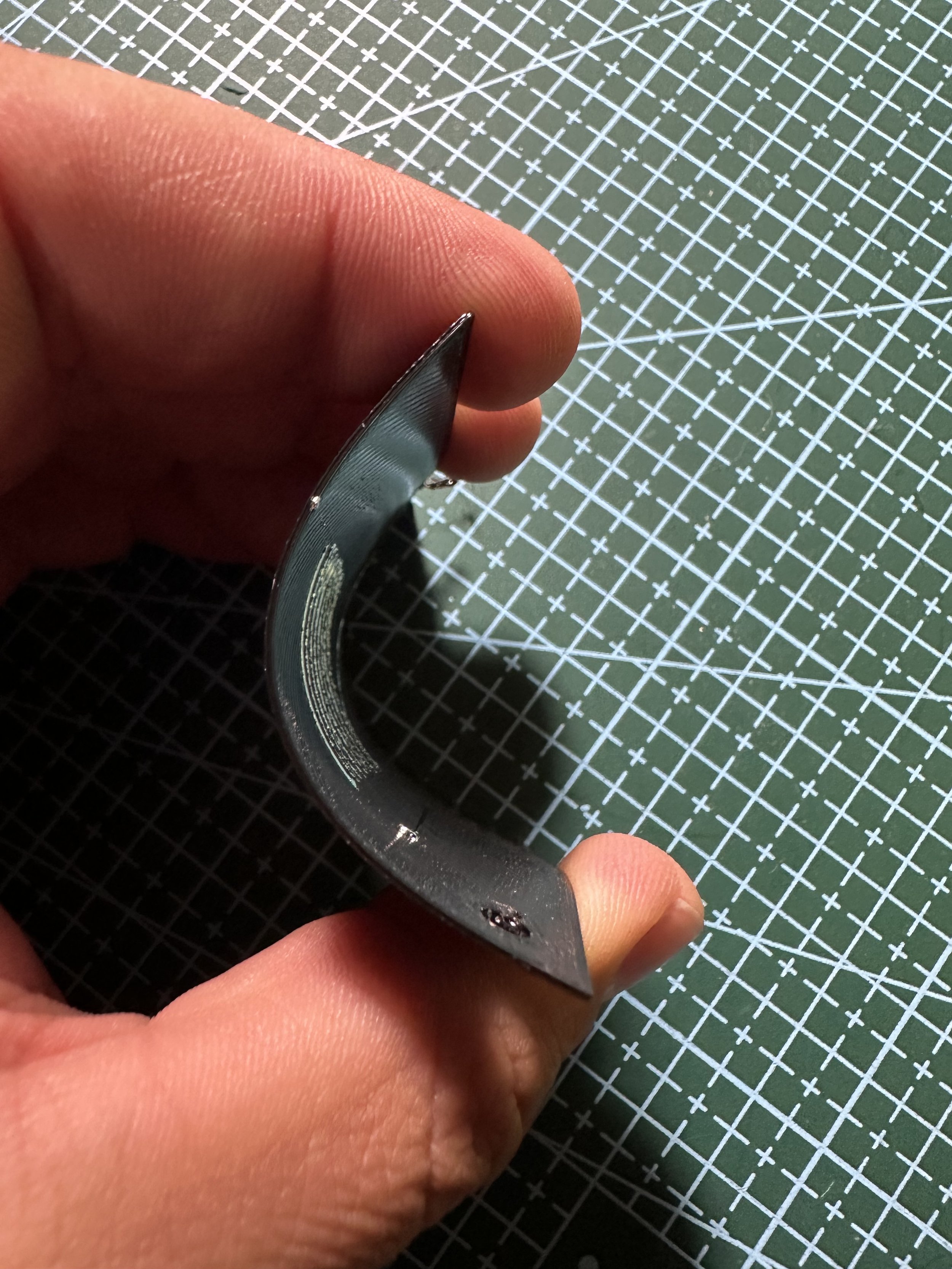

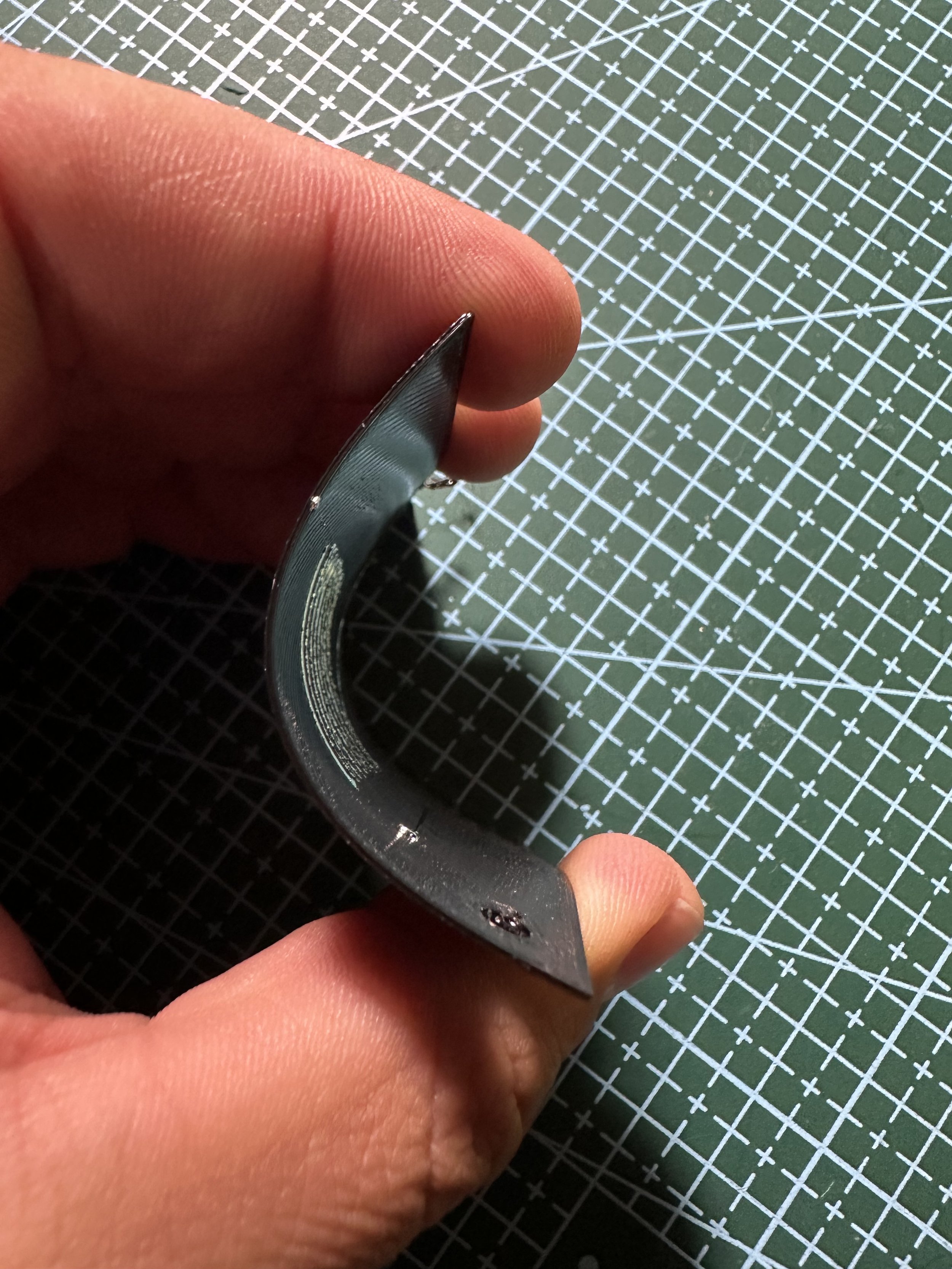

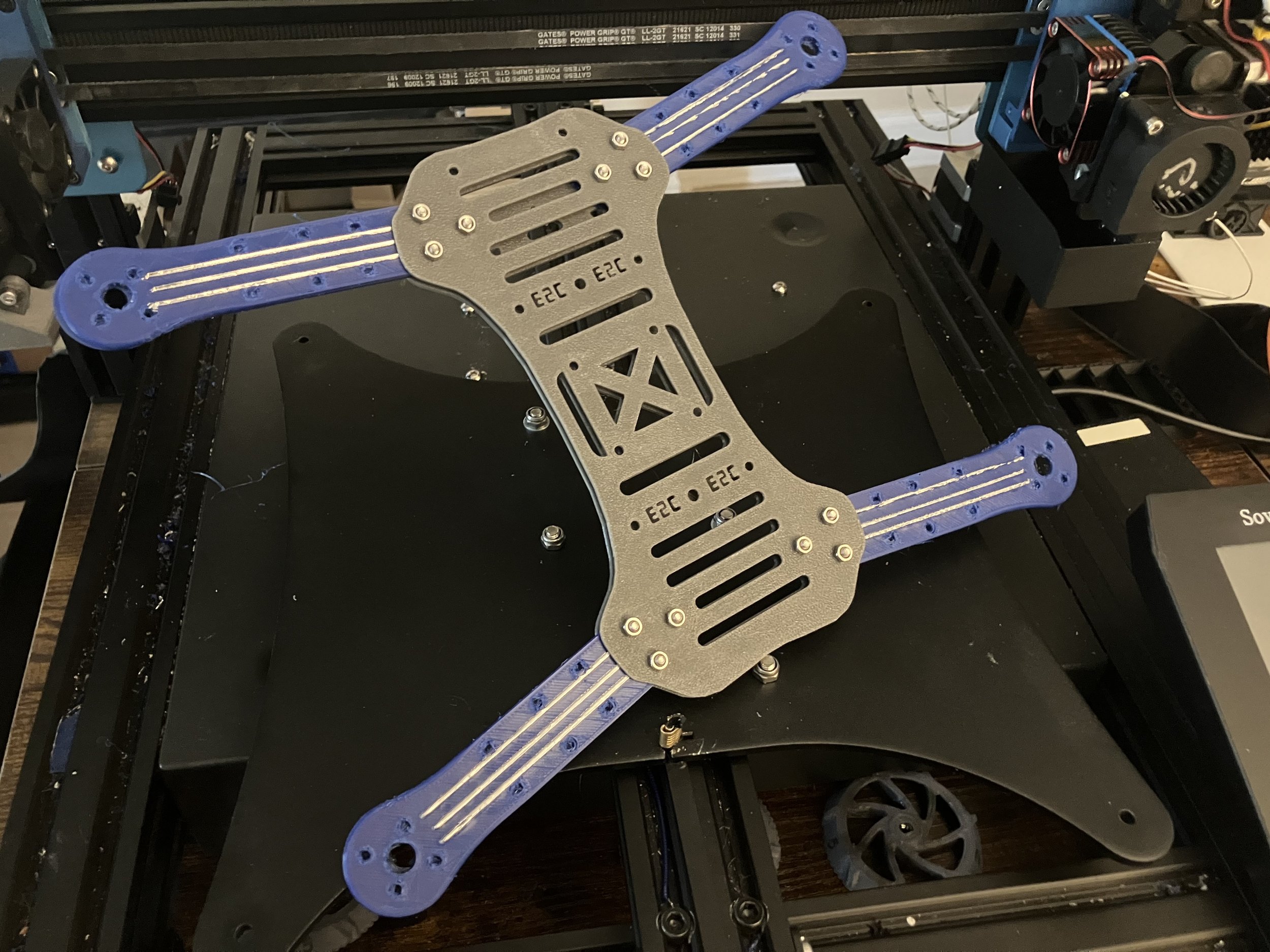

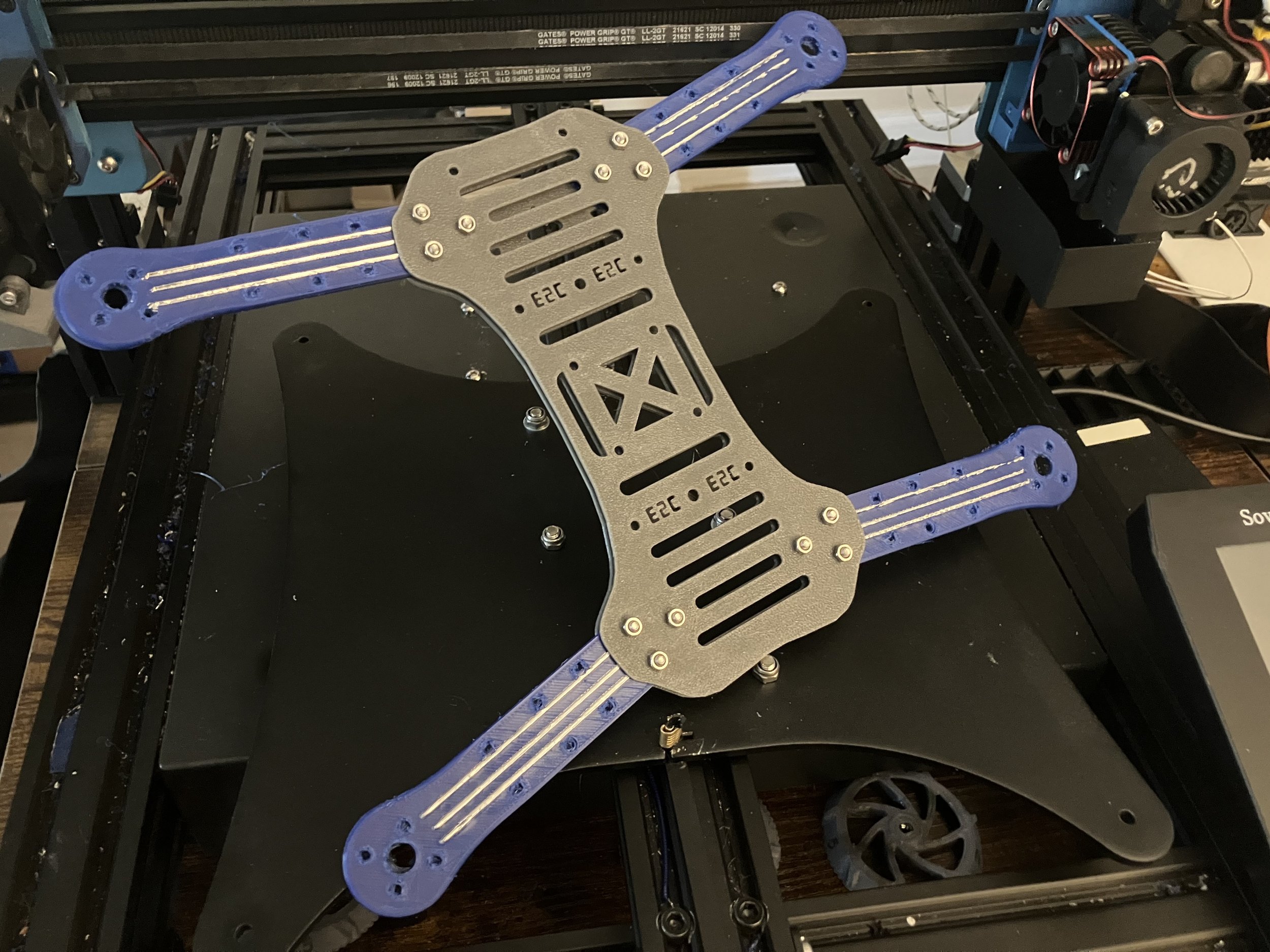

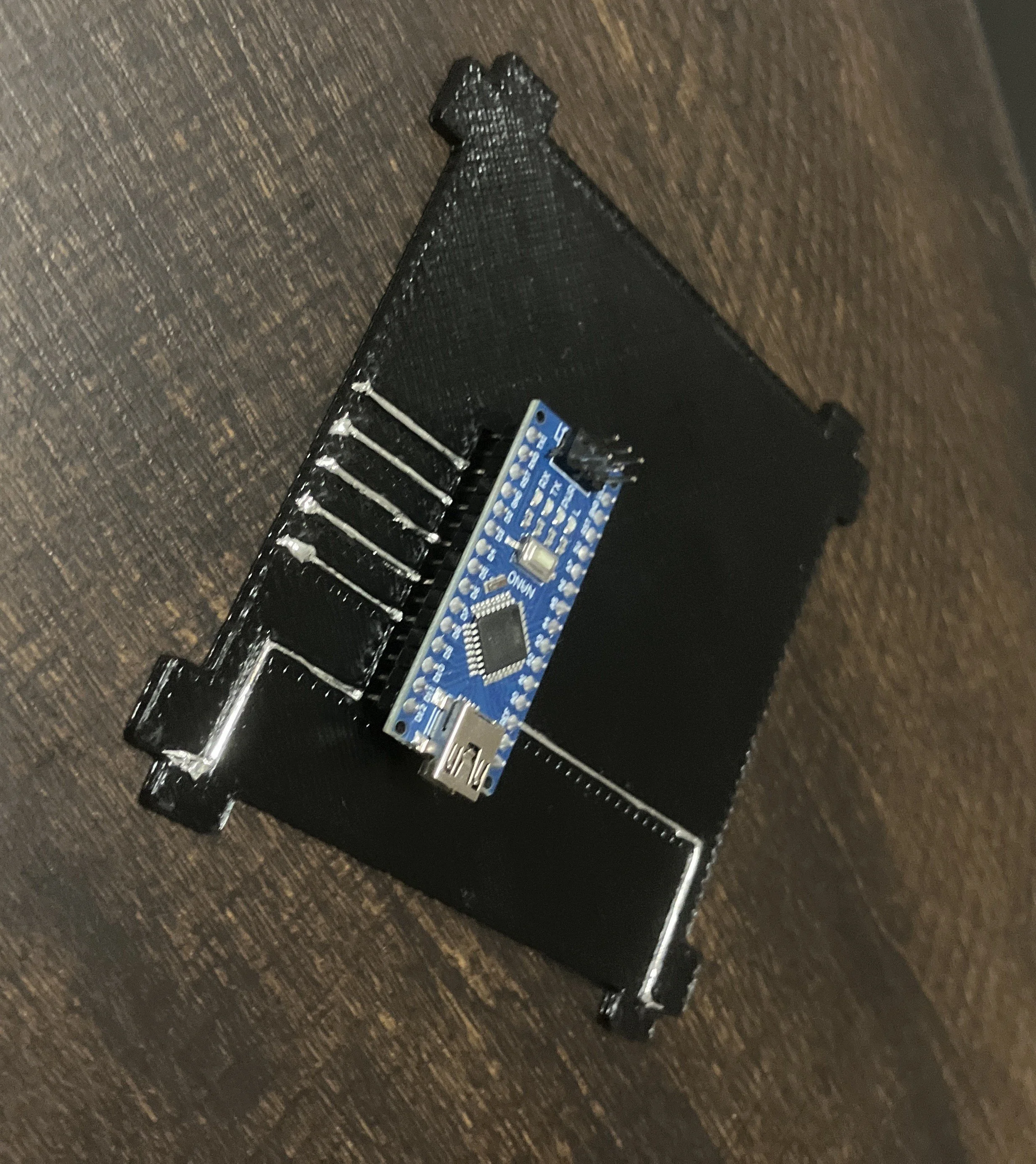

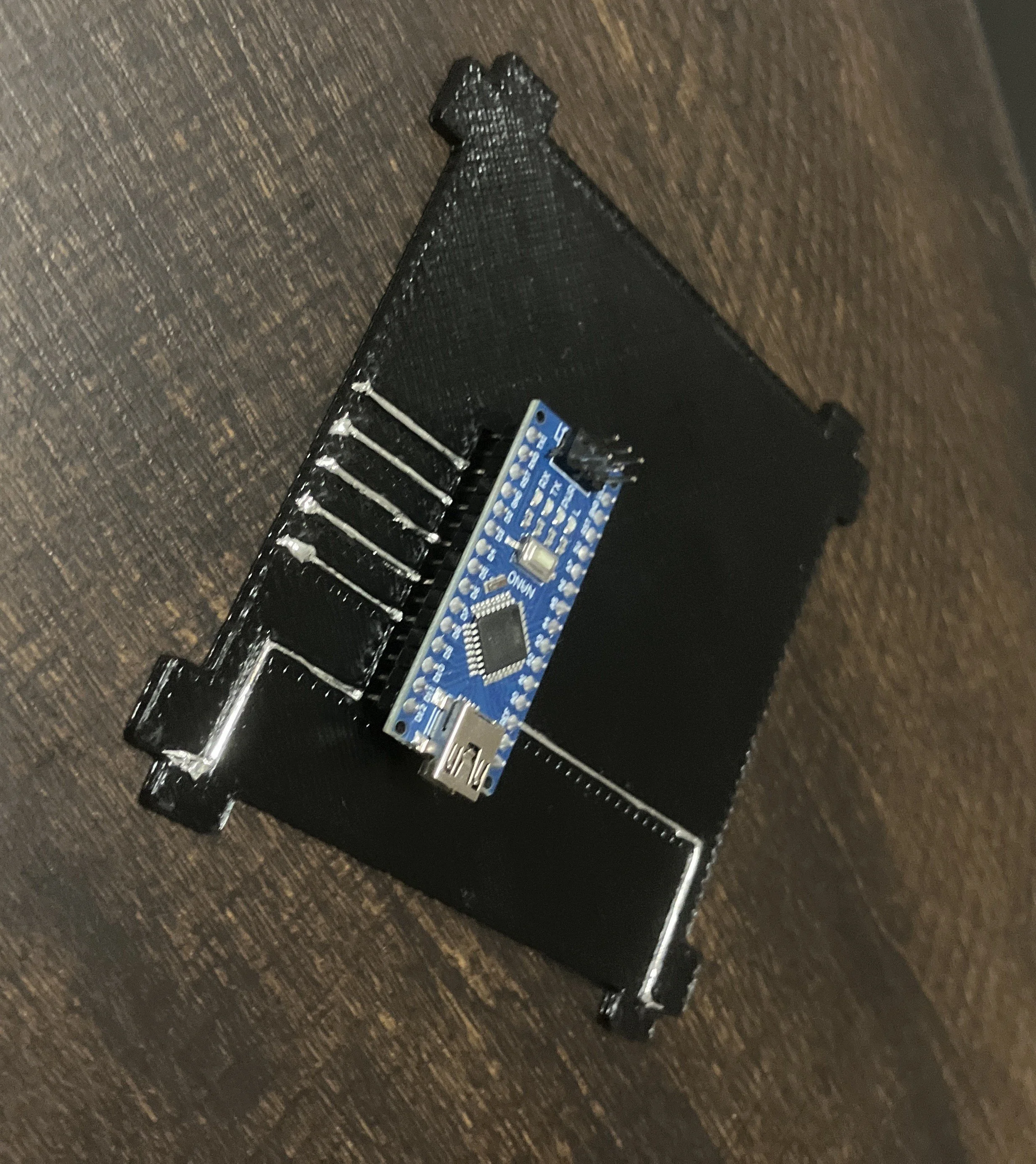

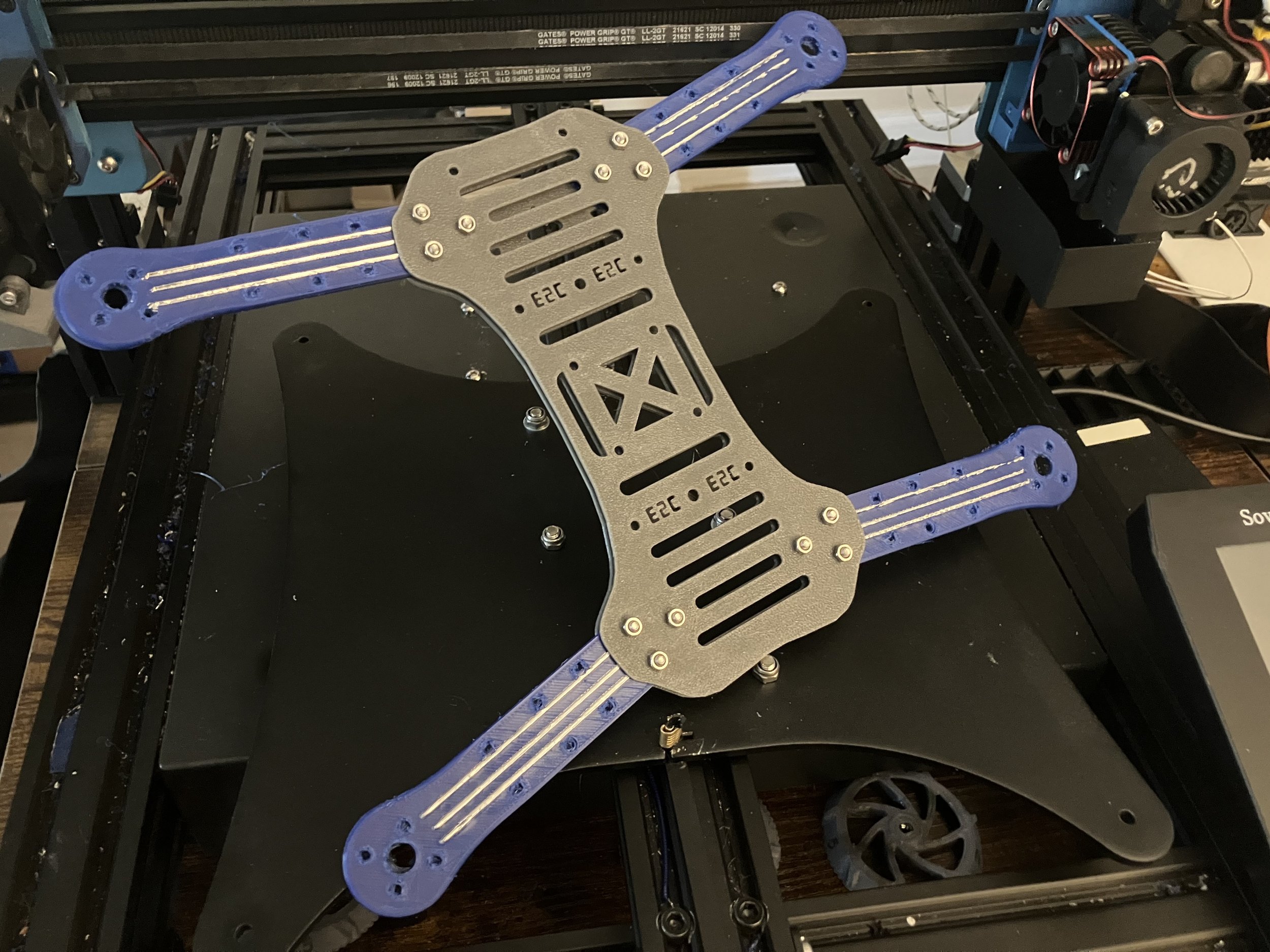

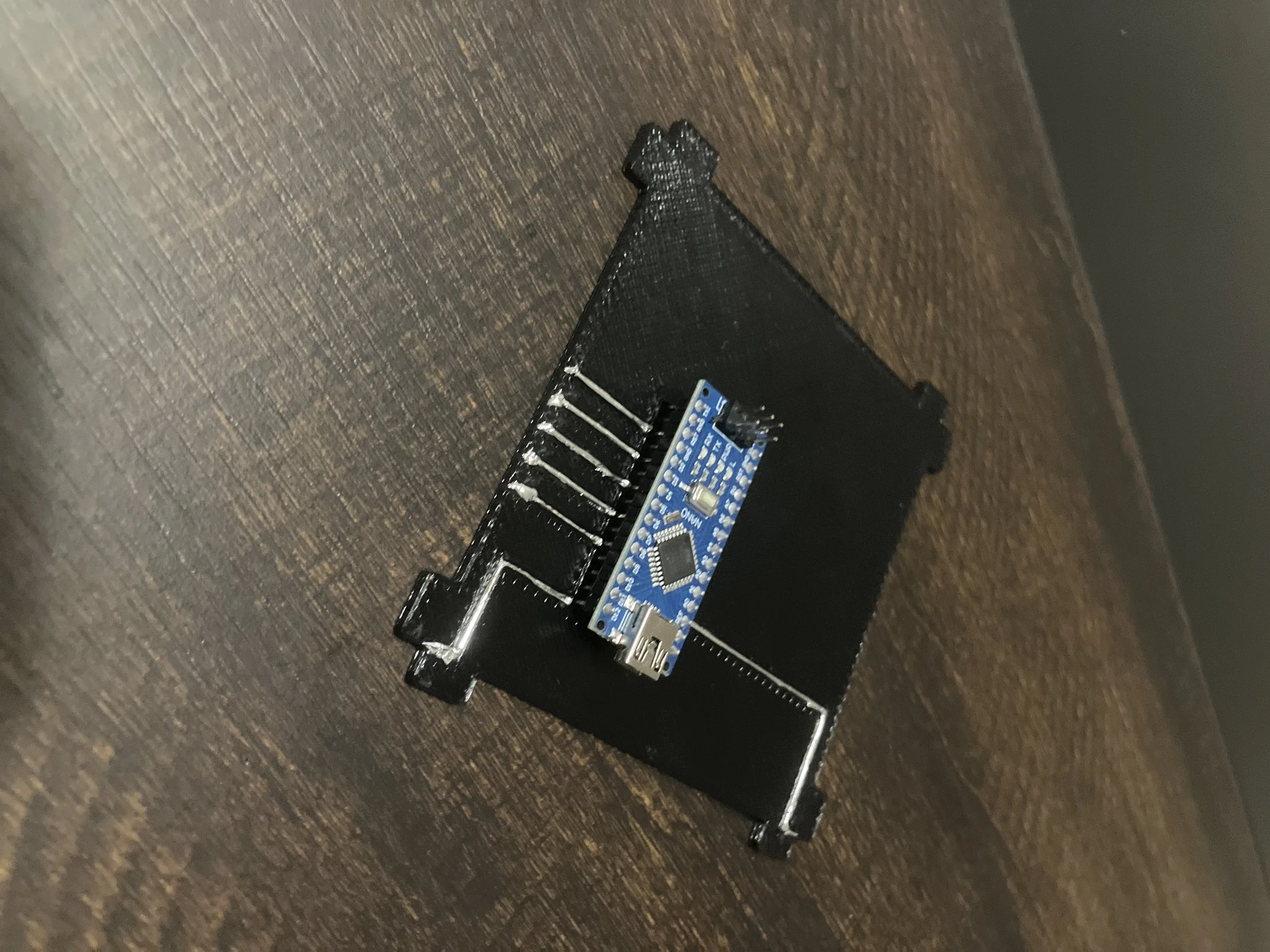

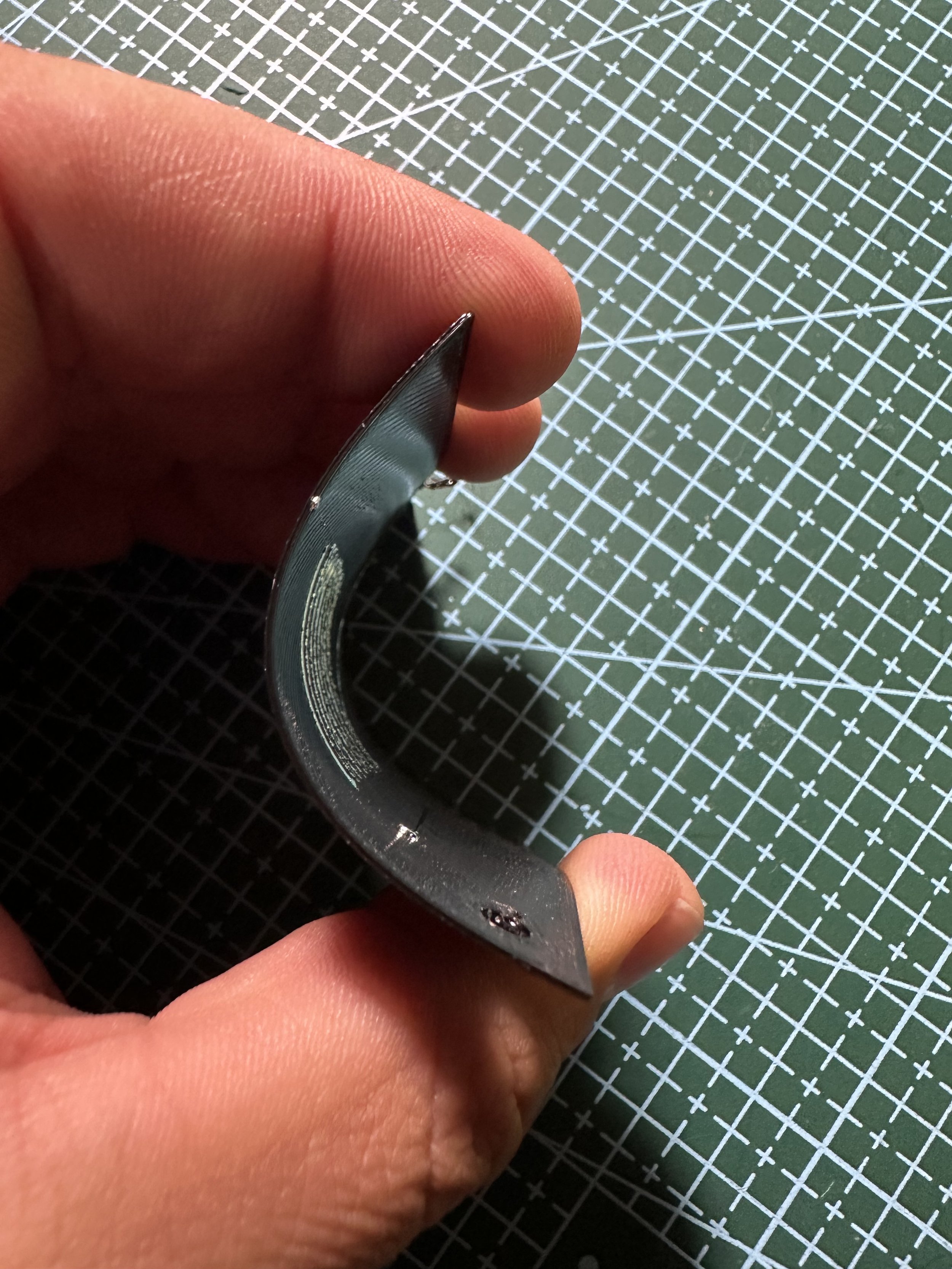

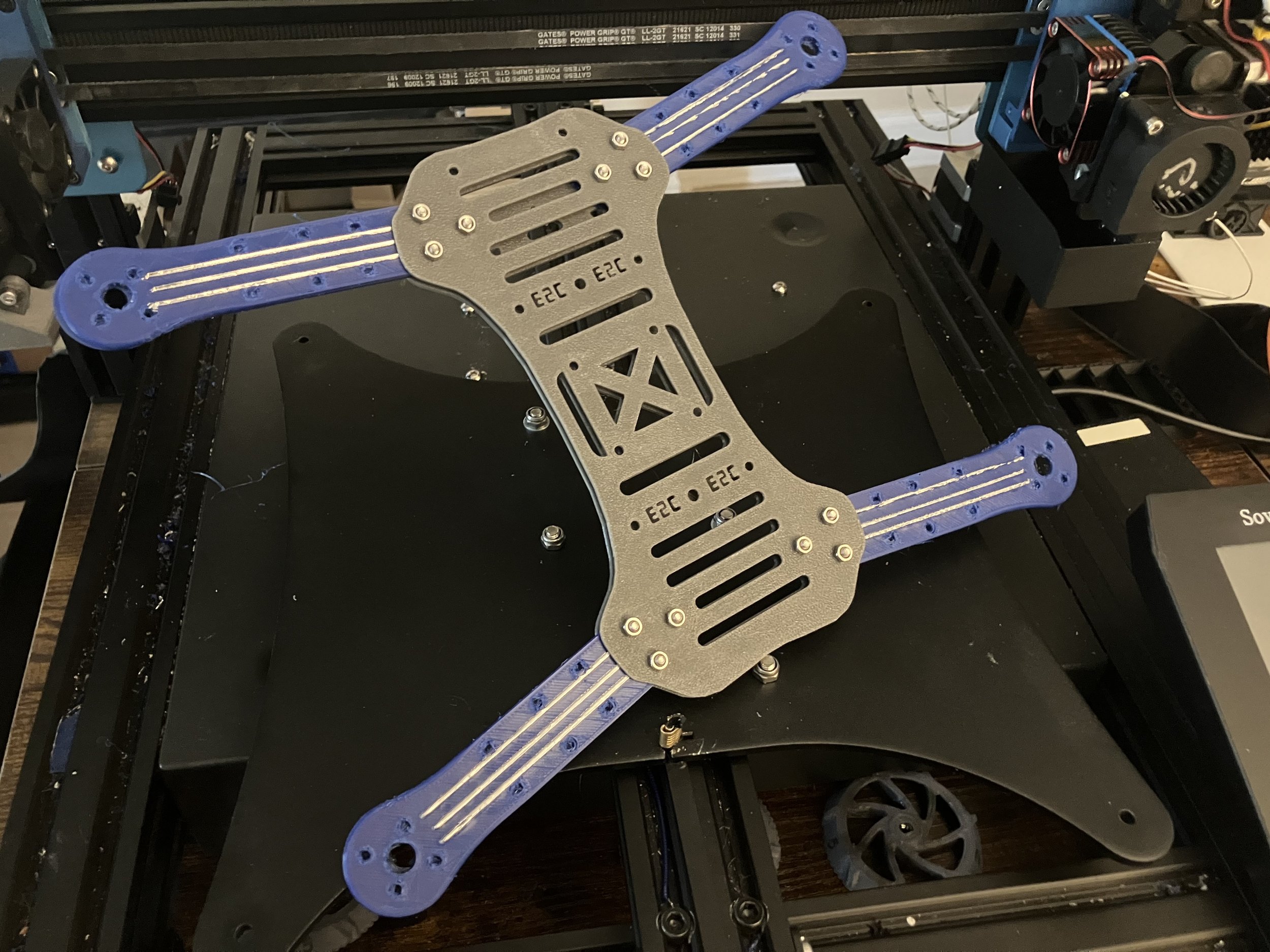

Flexible & Embedded Ready: Cu29 circuits can be printed directly into non-planar parts and flexible breadboard layouts.

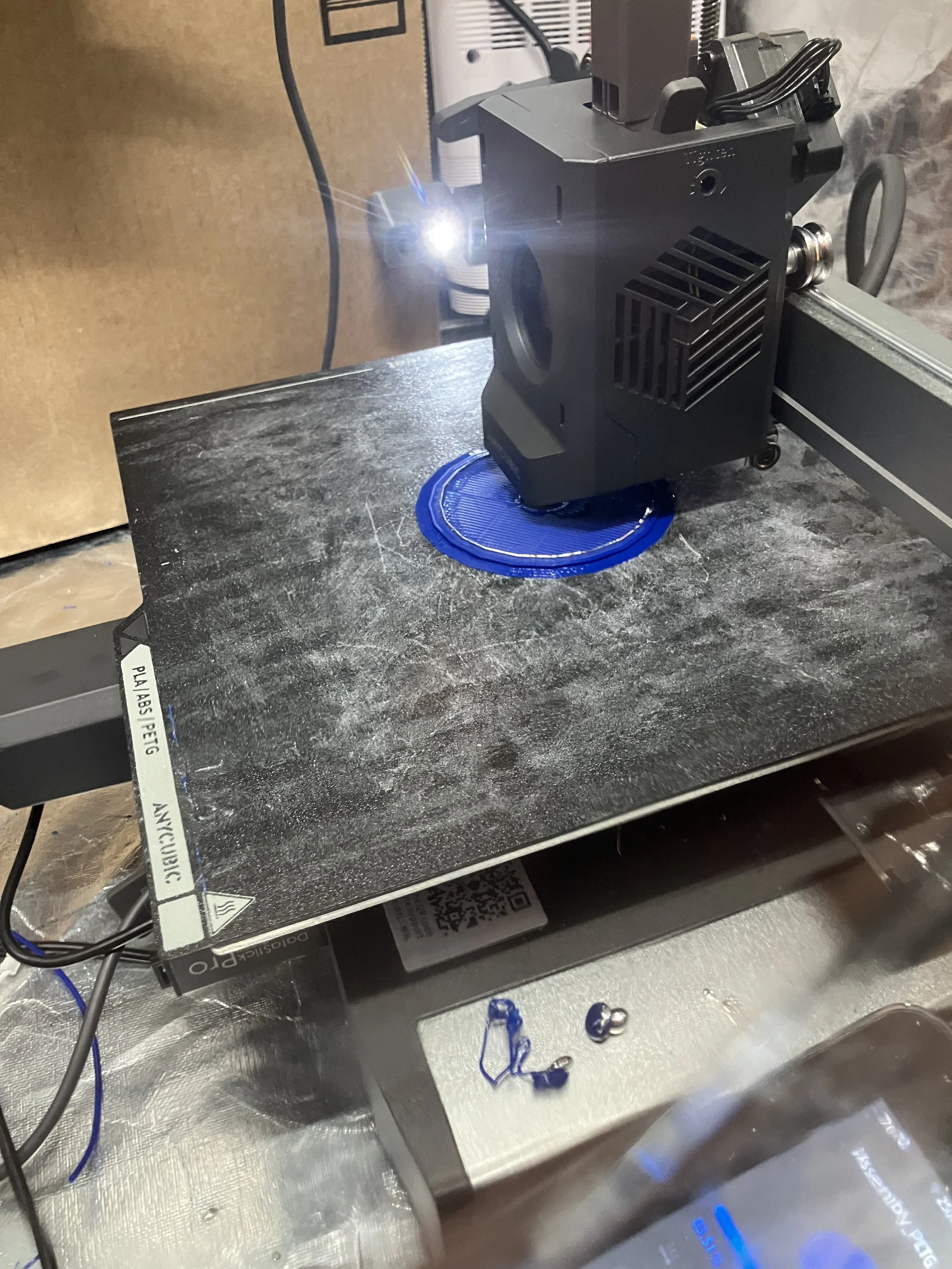

Cross-Platform Compatibility: Works on <$400 printers like the Sovol SV04 or more expensive printers like the Bambu Lab X1, as well as high-end commercial systems.

Trusted by Leaders

NASA, Northrop Grumman Space, Boeing, the U.S. Army Devcom Army Research Lab, and KBR are already using Cu29 for next-gen applications, ranging from CubeSat electronics and printed antennas to embedded RF shielding and high-voltage sensor circuits.

Applications

Aerospace & CubeSat avionics

Conformal RF and EMI shielding

Defense-grade sensors and circuits

Flexible electronics & breadboard prototyping

Radiation-hardened, embedded electronics

Specifications

Material: Proprietary Tin-Copper Composite (No Polymers)

Form: 1.75mm and 2.85mm filament

Resistivity: 1.226×10⁻⁵ Ω⋅cm

Printer Compatibility: FDM/FFF

Optimal Nozzle Temp: 232–260°C

Trace Resolution: Dependent on nozzle orifice size ( 0.2mm to 1.2mm)

🚨 Limited Inventory. Demand from DoD and aerospace primes is accelerating. Secure your spool before quarterly allocations close.

📩 For bulk or custom orders, contact us at info@kuprosinc.com

Cu29™ All-Metal Conductive Filament for FDM/FFF 3D Printing

Power-grade conductivity. Zero post-processing. No million-dollar printer required.

Kupros’ Cu29 is the world’s first all-metal, high-voltage and high-amperage conductive filament designed to bring industrial-grade Additive Manufactured Electronics (AME) to the desktop. Whether you’re printing embedded circuits, antennas, sensors, EMI shielding, or custom RF devices, Cu29 delivers unmatched conductivity and seamless integration into your polymer-based components, using off-the-shelf 3D printers or industrial printers.

Choose Your Trace Length

We’ve got four spool sizes depending on how deep you want to dive in:

50g – $250: Prints ~50 meters of average sized conductive traces

100g – $450: Prints ~100 meters of average sized conductive traces

0.5kg – $1,850: Prints ~½ kilometer of average sized conductive traces

1kg – $3,500: Prints ~1 kilometer of average sized conductive traces

Key Features

Massive Resistivity Advantage: 1.226×10⁻⁵ Ω⋅cm. That’s over 48,000% more conductive than polymer-based filaments.

True High-Voltage Performance: Validated at 12,500 volts and 5 amps.

No Post-Processing Required: No sintering, plating, curing, or chemical cleanup.

Precision Engineering: Supports traces as fine as 0.12 mm and up to 1.2 mm wide.

Flexible & Embedded Ready: Cu29 circuits can be printed directly into non-planar parts and flexible breadboard layouts.

Cross-Platform Compatibility: Works on <$400 printers like the Sovol SV04 or more expensive printers like the Bambu Lab X1, as well as high-end commercial systems.

Trusted by Leaders

NASA, Northrop Grumman Space, Boeing, the U.S. Army Devcom Army Research Lab, and KBR are already using Cu29 for next-gen applications, ranging from CubeSat electronics and printed antennas to embedded RF shielding and high-voltage sensor circuits.

Applications

Aerospace & CubeSat avionics

Conformal RF and EMI shielding

Defense-grade sensors and circuits

Flexible electronics & breadboard prototyping

Radiation-hardened, embedded electronics

Specifications

Material: Proprietary Tin-Copper Composite (No Polymers)

Form: 1.75mm and 2.85mm filament

Resistivity: 1.226×10⁻⁵ Ω⋅cm

Printer Compatibility: FDM/FFF

Optimal Nozzle Temp: 232–260°C

Trace Resolution: Dependent on nozzle orifice size ( 0.2mm to 1.2mm)

🚨 Limited Inventory. Demand from DoD and aerospace primes is accelerating. Secure your spool before quarterly allocations close.

📩 For bulk or custom orders, contact us at info@kuprosinc.com